Q: Why Should You Store Sheet Metal Efficiently?

To increase your capacity, throughput, and profits! Sheet metal storage and handling is one of the most overlooked aspects of fabrication businesses; without good processes in place, fabricators get buried in their own material without ever capturing those costs. Material handling costs are very real, and they add up extremely quickly.

Q: How Do I Store My Sheet Metal More Efficiently?

Loaded question! This largely depends on your size, variety, volume, footprint, and other factors. In a nutshell, it starts with allowing for quick & independent access to your material, while also decreasing your current storage footprint. Once you minimize time and reduce space, you’ll begin to reap the benefits of efficient FIFO control, protected material, and protected operators.

Q: Where Do I Start To Efficiently Store My Sheet Metal?

- Measure; perform time studies. If your operators/material handlers track time spent daily locating/unburying/handling material, you’ll quickly realize where you need to place priority.

- Ask for help. It’s what we’re here for. Explain your current methods to us, and we’ll dive in headfirst. We’ve seen a LOT of shops, and we’re happy to help. We’re low-pressure, and if we don’t have the right product to help you, we’ll refer you to someone who does.

Q: Is My Shop/Equipment A Good Fit For LEAN Sheet Metal Storage Racks?

If you cringe when we ask any of these questions, then yes, you are likely a good fit:

- Do you consider your shop “tight on space”?

- Do you spend time looking for raw material on your shop floor?

- Do you spend time unburying material once it has been found?

- Are your machines producing parts while you’re looking for the material?

- Is your material ever damaged (scratched surfaces, bent corners, warped)?

- Have you ever had wooden pallets break/snap?

- How much cost is amortized into your cost of steel to cover the wooden pallet?

- How do you dispose of wooden pallets?

- Have you had any safety incidents with raw material?

Q: How Expensive Is A Sheet Metal Storage System?

- Of course, it depends. As a ballpark, the investment is much less than what you’re currently spending on material handling. After we understand your specs, we’ll be able to offer our best price for your opportunity.

- Contact us for our ROI calculator. That way we can do the work for you! ROI is typically a much shorter cycle than our customers initially anticipate. Plus, most customers find out that their current method of material handling and storage costs more to operate than it costs to buy and implement our storage systems.

Q: Why are there different styles of sheet rack cartridges?

- Depending on your volume, consistency, supplier relationships, and commitment to safety, we offer something for everyone.

- The Re-Rack cartridges are the most robust offering, which are designed to be shuttled back and forth with your raw material suppliers. Read more about the Re-rack Cartridge Style here.

- The Safety Block cartridges are an economical alternative to the Re-Rack cartridges, with nearly all the same features. However, they do not directly stack on top of each other like the Re-Rack cartridges do. Read more about the Safety Block Cartridge style here.

- The Plain cartridges are just as they sound – plain. They do not have perimeter features to keep the material in place, and they are typically built size-on-size to the material, much like a traditional wooden skid. Read more about the Plain Cartridge Style here.

Q: Are all different styles of sheet rack cartridges universal?

No. At least, not typically. We can adjust if you have specific requirements, but for the most standard offerings see the cartridge sizing chart here.

Q: How much weight can each sheet rack cartridge hold?

5,000 pounds.

Q: What Sheet Sizes Are Compatible With Lean Sheet Metal Storage Systems? Can I Create Custom Sizing And Spacing Of The Rack?

- Most common sheet size is 4’x8’, 4’x10’, 5’x10’, 6’x10’ and 6’x12’.

- If your sheet size(s) does not fall within those sizes, we can still create a solution for you. We have extensive experience providing custom solutions.

Q: How Can I Get A Quote for steel storage racking?

- Share with us. Each project is custom-built to your exact specifications, and we need to understand your goals, constraints, and opportunities.

- Be prepared to share any (or all) of the following details:

- Sheet Size

- Number of pallets currently in your shop

- Ceiling Height

- Bundle Height (material stack height) on individual pallets

- Weekly consumption of material

- Loading automation attached to lasers/punches

- If you’re able to send any pictures of your current material storage area, those always help us immensely.

Q: What Is The Lead Time For A Sheet Metal Storage Rack?

Typical lead time for a sheet rack is 6-7 weeks. We build-per-order to ensure we’re meeting your exact specs, and we will always do our best to work with your scheduling needs.

Q: How Much Clearance Is There Between The steel storage Shelves?

- We recommend at least 1.5” from the top of your raw material to bottom of the angle iron above it. For example, if you have 22 shelves within a 14’ tall rack and a max “material stack height” of 2.5”, there will be 1.75” of clearance between the top of the stack and the bottom of the angle iron above it.

- We will work with you using renderings to dial in the right spacing for your exact application.

Q: Do Your sheet rack Cartridges Slide Out Of The Rack Like A Drawer?

No, we do not offer hand-operated sliding drawers. There are a few other manufacturers that we can connect you with, but the rolling slide-out drawers are not our product. Instead, ours are accessible steel storage racks with forklift, which allows us to go much higher and better use the vertical space in your shop.

Q: Do you offer carts to put the steel racking cartridges on?

- Yes, absolutely. In fact, they are great carts! For full size carts, we use a pivot mechanism to allow maneuverability in your shop floor. The carts have swivel casters in the 4 corners, and rigid casters in the middle, which means the center of the cart is the “pivot axis” = shorter turning radius.

- We especially recommend these if you are manually loading your machines. We can spec the cart(s) so they are at machine height and will minimize the height differential the sheets need to travel. For example, if you’re using a jib crane, you won’t need to run the suction cups all the way to the floor just to grab the next sheets…minimize the distance traveled with a strategically placed cart.

Q: How Do You Transfer Material From A Wooden Pallet To A LEAN steel Cartridge For Storage?

A lot of people call it a depalletizer, but we prefer “Pin Table” because we use a series of sliding pins along a grid framework to successfully and efficiently transfer sheet metal off a wooden pallet or runners onto a LEAN sheet metal storage cartridge. See more info about the 'Material on Runners' process here.

Q: How big is a Sheet Metal Storage Rack Footprint?

Please contact us and we would be happy to provide you with the footprint of our sheet metal storage systems. We can either send a drawing of the rack itself, or you can send us a DXF of your plant layout, and we can see where they’d fit.

Q: What Is The Concrete Requirement For a sheet metal storage rack?

Pending the exact specs of your system(s), your concrete must be able to support 3,000 PSI across a level surface. If you have concerns about your concrete, we do offer larger foot pads for the sheet racks, which can help further distribute the load.

Q: How Are LEAN Sheet Metal Storage Systems Installed? How Long Does It Take? What Equipment Is Needed?

- The sheet metal racks are shipped in a series of flat panels (side walls & back wall) that are stood up and joined together with supplied hardware.

- They can be assembled using either an overhead crane or a forklift – typically customers do not use any outside rigging services, but we’re happy to point you in the direction of local companies if you need assistance.

- Rule of thumb is 2-3 hours for 2-3 operators for the first unit, and 1-2 hours for each additional unit after that.

Q: Does the steel storage rack Need To Be Placed Against A Wall Of The Building?

No. Each sheet metal rack has (4) anchoring holes for securing the unit to the floor.

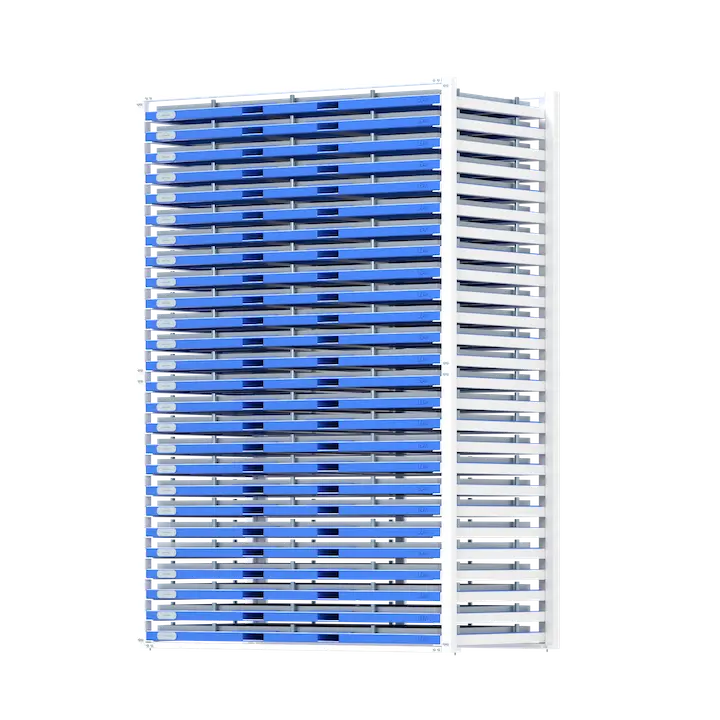

Q: Can We Do Custom Colors on the sheet metal rack?

Of course! Blue and white is our default color scheme, but we’re more than happy to swap out for the powder of your choice. Just let us know what you’d like to have on your shop floor, and we’ll make it happen! We’re still waiting for the first hot pink order…

Q: Can You Visit Us?

- Yes – our doors are always open to you. We are located about 30 minutes outside Milwaukee, Wi.

- Likewise, we have many skilled representatives across the country that would be thrilled to meet you at your facility and measure your project with you in-person.

- We also have many happy customers scattered across the US that (pending their line of work) would be willing to show you the units in their facilities.

Q: Do You Have A Referral Program?

- Absolutely! We appreciate and recognize our customers that refer us to other businesses. Please contact us for more information!

- We strive to satisfy our customers to the level that they recommend us to friends.