Q: Why Would I Need A Pin Table/Depalletizer?

A pin table is utilized to swiftly transfer sheet metal from wooden pallets to a lean cartridge, liberating the material from the pallet in just a few seconds.

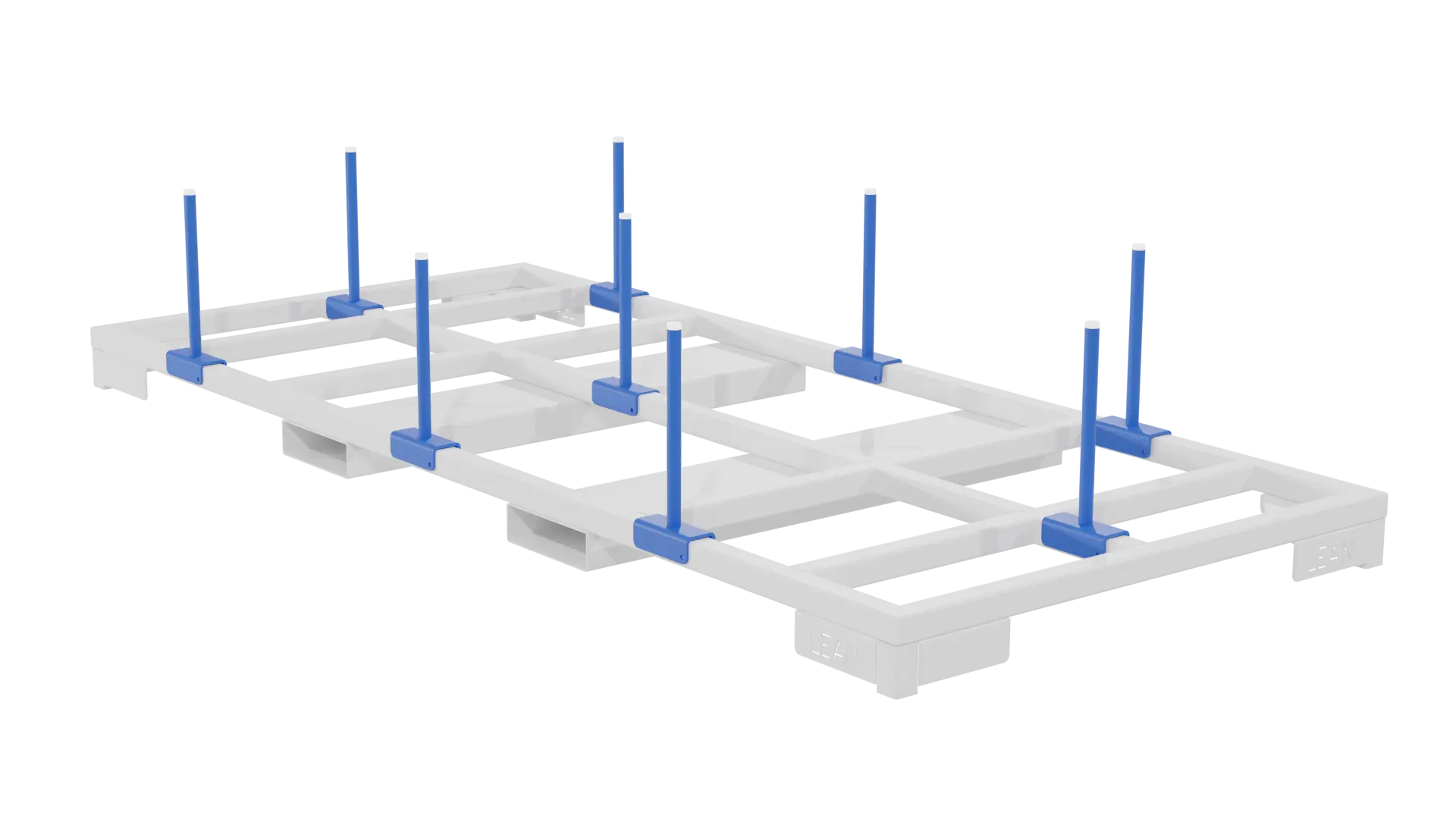

Q: What is included with the LEAN Pin Table/Depalletizer?

The depalletizer includes twelve upright pin weldments that can be repositioned within the pin table's framework. These pin weldments are positioned within the pallet's windows to effectively engage the sheet stock, ensuring an even distribution of load as the material is lowered onto the weldments. This process effectively separates the material from the pallet.

Q: What Does The Sheet Metal Transfer Process Look Like Utilizing A Pin Table?

The pin table offers user-friendly operation, enabling you to detach sheet material from wooden pallets efficiently. Refer to the accompanying video to observe the process of transferring sheet metal using a LEAN Pin Table/Depalletizer: