PICKING THE BEST-FIT LEAN STORAGE SYSTEM

1 . How tall are the racks?

When designing a rack, we start from the outside and work our way in – the first step being the overall height. By determining the height, we’ll have better insight into how many storage locations we can offer within a single footprint. So, what is your overall ceiling clearance? If you’re 20’+ clear, we’re likely going to recommend our tallest system – 14′. But, there are other factors we need to consider as well:

Do you have an overhead crane in the material storage area? If yes, subtract its drop height.

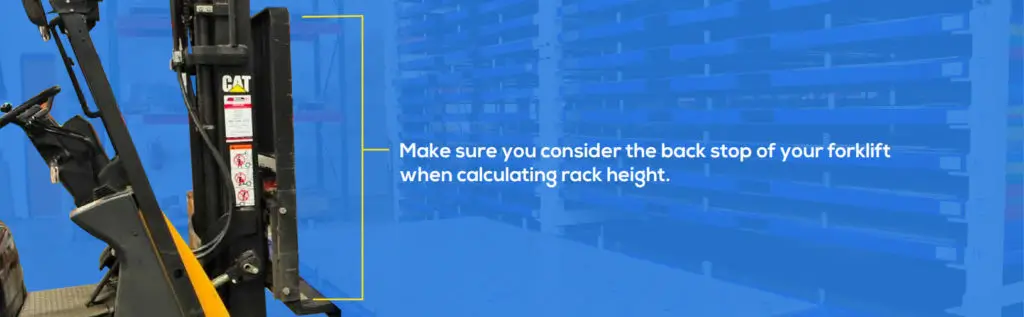

Do you have a mast / back stop on the forklift? If yes, subtract its height.

Do your (current) forklifts have a maximum reach height? If yes, this is likely the limiting height.

Once dialing in these details, we’ll know the framework that we can begin building. Then, we get to the fun part of deciding what to put inside it! We’re going to help you every step of the way to ensure you’re 100% happy with the end result.

Our tallest, most common racks are 14′ tall; we’ve also built them as short as 8′ tall for customers with ceiling and/or forklift restrictions. Regardless of what the height ends up being, we want to make sure we’re maximizing your available vertical space.

As long as your volumes support it, we typically recommend the tallest racks that you can fit in a specific area. By doing this, you achieve the most density within a single footprint. Remember, you still have independent access to each cartridge, no matter how tall the rack is. We want to help you save space and make smart long term decisions.

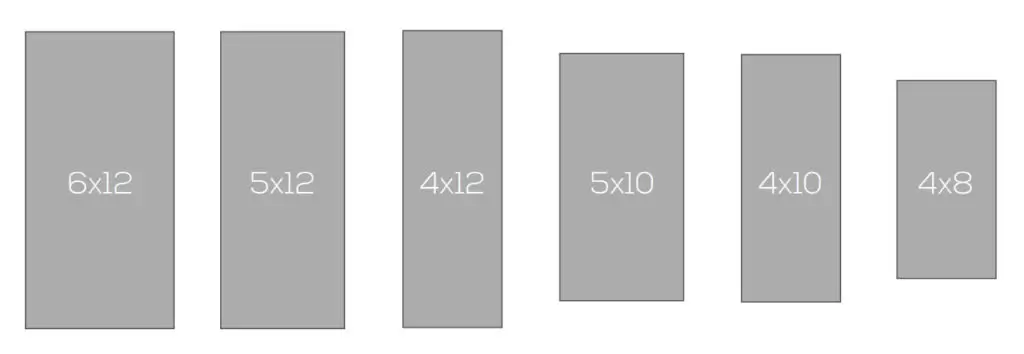

2. What is your sheet size?

Sheet size affects both price and footprint of a LEAN storage system, so it’s important to give a careful look at both your current operations and anticipated operations for the coming years.

When considering sheet sizes, consider the 80/20 rule; chances are, you do not have ALL the same size sheets on your floor. So, what is your highest volume size? Depending on your flat blank size(s), we’ll work with you to achieve 1) the fastest ROI, and 2) the biggest win to begin with.

3. How many pallets are currently on your floor?

Collecting current inventory counts is a great way to begin calculating the number of racks you’ll need. However, we encourage you to start small with one or two towers, and use those to gain the buy-in from the floor operators. Once you’re able to show them how much easier and more efficient their jobs have become, they’ll be extremely receptive to phase 2 to tackle the rest of the material.

Other factors to consider that can affect inventory levels:

Are you buying new cutting technology (ie a faster laser)?

Are expecting to be awarded larger contracts?

Are your customers requesting quicker turns, causing you to hold their material at-the-ready on your floor?

Are you currently purchasing efficient lot sizes on your high-runners?

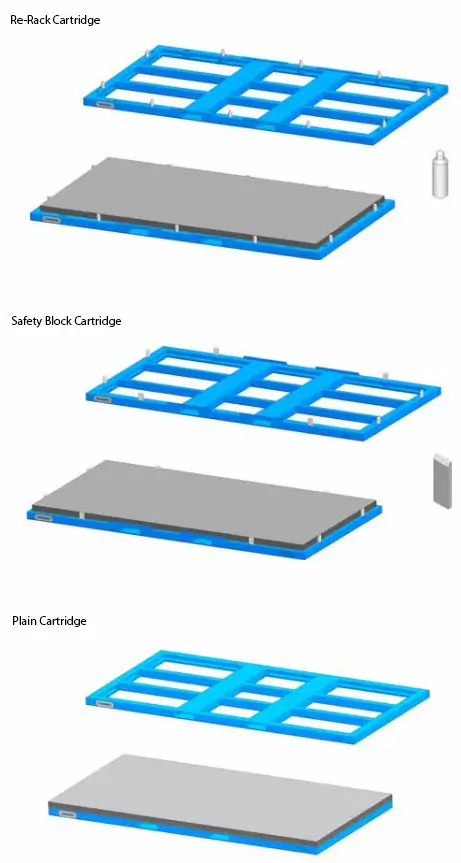

4. Which LEAN cartridge style best fits you?

We realize that not everything is ‘one size fits all’.

That is why we offer three cartridge styles to best suit our customers needs.

Re-Rack – recommended for our high-volume customers receiving multiple shipments of steel weekly. Send us your material list/Kanban and we can gauge what makes the most sense for you. This is intended to be shipped to-and-from your steel supplier to completely eliminate the need for messy wooden pallets.

Safety Block – highly recommended to all of our customers. This style offers 8 removable perimeter blocks that keep material in tight stacks. This protects your material and people when the cartridges are being moved via any type of rigging.

Plain – our basic style of cartridge. Material fits size-on-size to the cartridge without perimeter features.

Both the Re-Rack and Safety Block cartridge style are great for highly aesthetic materials. For example; stainless, pre-painted, very thin gauge, etc.

Contact Us For More Information

5. How tall are your material stacks?

Understanding your material stacks is critical when deciding how many shelves we can fit inside each of your towers. For example, to hit the 5,000 pound load rating, a 48×96 bundle of sheets is going to much taller than a 72×144 stack. Depending on your sheet sizes and purchasing practices, we’ll work together to design the system that maximizes your storage while also give your operators ample room within the rack.

6. How do you move your sheet metal?

The LEAN cartridges are intentionally constructed with oversized forklift tubes for easy access. When loading the cartridges into the high-density tower (figure B), a forklift must be used. And when transferring material to or from a cartridge (figure A), an overhead crane and sheet lifter may be used, but it is not required. With the LEAN systems, every process is achievable and efficient with a forklift, which also gives the most flexibility to your operations.

7. What color would you like your storage system(s) to be?

Our standard colors are a white rack with blue cartridges. If that doesn’t fit the color theme for your shop, we are able to use any RAL standard color from the Sherwin Williams PowderDura color deck.

8. Where do you plan to put the rack?

Have you considered what area of your building you receive material and where the rack is located in correlation to the equipment that will be cutting/processing the sheet metal?

By sending us a layout of your facility or us sending you a footprint rendering for the rack, you can plan ahead. This ensures smooth assembly and positioning for the rack to optimize your flow and ensure enough space for safe and easy handling.

Storage density by the numbers

The picture below shows 90 cartridges that hold 5000 lbs. of material each within 884.5 sq. ft.

All material is fully accessible and fully protected on five racks. (4) 5’x10’ and (1) 4’x8’ with 18 feet in between racks. All five racks are 12 feet tall. We can comfortably store (90) cartridges of material in less than 1,000 square feet @ 12 feet tall, or (110) cartridges @ 14 feet tall.

You do the math. What is the square footage of your material storage area? Is each bundle protected and accessible?

Now that you’ve planned the details of your storage system, contact us today so we can provide you with a quote!